Construction and installation of new feed line

As part of the expansion of their product range, this customer was looking for a feed line for supplying a new type of product to their existing production line. For this customer, we developed, constructed, tested and installed a completely new feed line on-site. Project management Risk assessment and risk analysis in accordance with European […]

Construction of extra production line

Due to a sudden need for extra production capacity, this customer was looking for a machine constructor who could build an extra production line in a minimum of time for their location in China. For this customer, CTESO built a copy of the existing production line, including the required adjustments and improvements, in just 5 […]

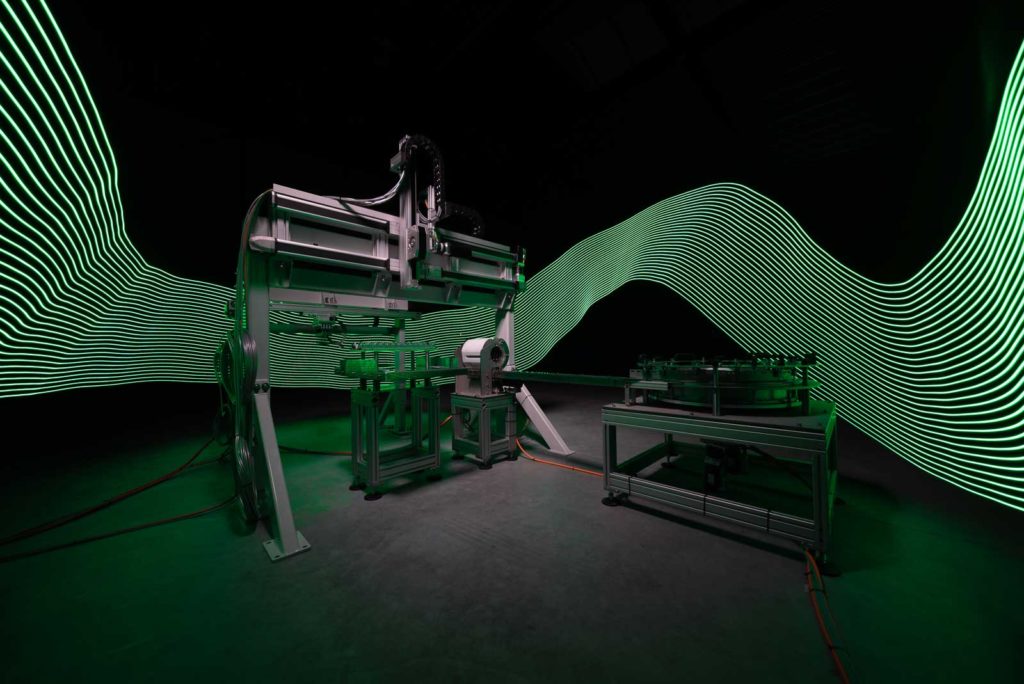

Complete automation, engineering, assembly and start-up of machines

Covess, located in Lummen, specialises in the manufacture of thermoplastic pressure vessels for the storage of gasses and liquids. For the purpose of expanding their market position, Covess is developing new machines for the wrapping of various types of thermoplastic tanks. To build and automate these machines, they were looking for a machine constructor who […]

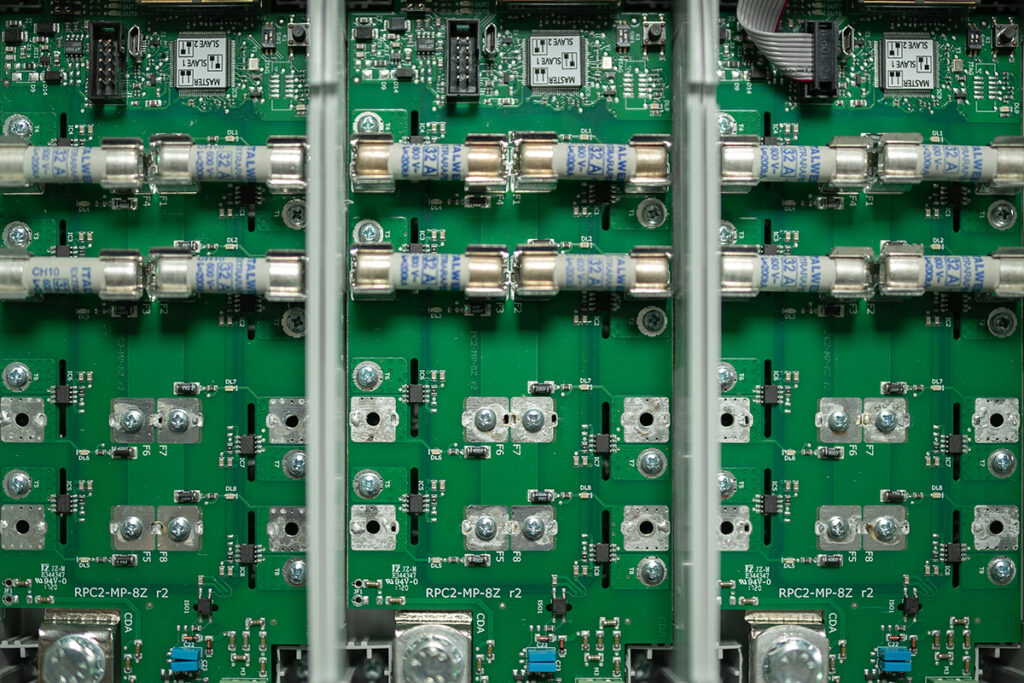

Machineconstruction for the automotive industry

The development and construction of advanced automation systems for a client in the automotive industry. This project includes the integration of 14 Kuka robots and high-quality object recognition cameras to ensure precise identification and handling of parts, which is crucial for an efficient production process. Additionally, we utilize 3D bin picking technologies, allowing the robots […]

Development of state-of-the-art machines

Qcify is located in California (USA) and is a global supplier of innovative machines used to perform automatic quality controls in the food industry. Because Qcify wants to focus on their core business, on their contacts with customers and on developing new and innovative applications, they were looking for a machine constructor who could build […]

Breakdown analysis, calibration and software adaptation

Veramtex, located in Brussels, specialises in the ecological treatment of all types of textiles. Several years ago, Veramtex purchased a machine for rolling large rolls of fabric. Since its commissioning, this machine has had several faults which could not be resolved, making the machine unusable. For Veramtex, we performed a breakdown analysis, calibration and software […]